Thermal Conductive Silicone Gap Filler for New Energy Battery Packs

Description

VS-GF2001 is a two-component, heat-curing silicone thermal conductive gap filler. It has good insulation and voltage resistance properties and thermal stability. It is safe and reliable to use, and has good rework ability. VS-GF3501 is used in new energy battery packs, automotive electronic control units, 5G communication base stations, power devices and heat sinks or machine casings, it can effectively remove air and achieve a good filling effect.

Features

- Excellent surface wettability

- Well insulation material

- High thermal, low heat resistance

- Continuous operating temperature:-40℃~+200℃

- Good resilience and long-term reliability

- Comply with RoHS and REACH certification requirement

- Complete specifications, accept customized

Technical Performance

| Item | Technical Data | Test Standard Method |

| Mixing Ratio | 1:1 | / |

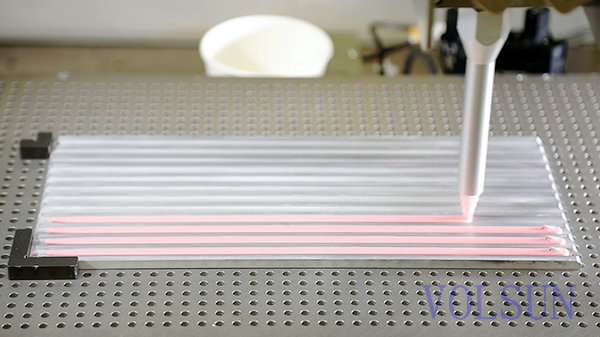

| Color(after mix) | Pink | Visual |

| Curing Condition | 100℃·30min | / |

| Thermal conductivity | 2.0±0.2 W/m·k | ASTM D5470 |

| Hardness | 70±10 Shore OO | ASTM D2240 |

| Density | 2.0±0.2 g/ml | ASTM D792 |

| Tensile Strength | >35 KPa | GB/T 528-2009 |

| Elongation | >10 % | GB/T 528-2009 |

| Dielectric Strength | >8 kV/mm | ASTM D149 |

| Volume Resistivity | ≥1.0×1014 Ω·cm | ASTM D257 |

| Dielectric constant(1000Hz) | <6.0 | ASTM D150 |

| Size | Package |

| VS-GF2001(Samples) | 50CC Two components/PC |

| VS-GF2001 | 400CC Two components/PC |

Note: Special size and packaging can be customized on request.

Instructions

- Clean the surface of the object to be bonded or coated to remove rust, dust, oil, etc.

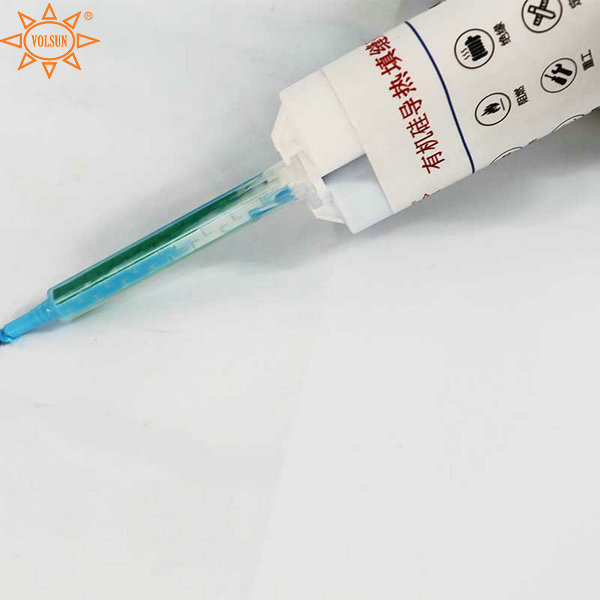

- Unscrew the glue cap, install the static mixer, and use the manual/automatic glue gun to squeeze the glue on the surface of the cleaned object

- After glue is completed, attach the second surface to it and apply a little pressure to fix it.

Precautions

- The use environment should be free of large debris or other pollutants to avoid affecting the adhesion of materials and objects

- Before the material is completely cured, avoid other objects contacting the material, which will affect the appearance and performance of the material

- This product should not be in the mouth and eyes. If it accidentally enters the mouth and eyes, rinse with water in time or go to the hospital for medical treatment.

Storage conditions Shelf life

-

The product should keep the lid tightly closed and store in the original packaging at room temperature and away from light

- The product shelf life is 9 months from the production date

Welcome to contact with us if any needs via volsun2006@szvolsun.com

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com