Volsun VS-TP1001 is a two-component 1:1 heat-curing silicone heat-conductive potting adhesive, which cures at room temperature or after heating to form elastic heat-conductive silicone rubber. It is specially designed for the manufacture of electronic and electrical products and modules, such as the potting protection of high-power power supply modules, frequency converters, sensors, etc., and the connection and fixation between on-board electronic devices and PCBs.

This product has the following excellent properties:

- Operating temperature: -70℃~+200℃

- Excellent mechanical properties and ductility

- Excellent thermal conductivity and aging resistance

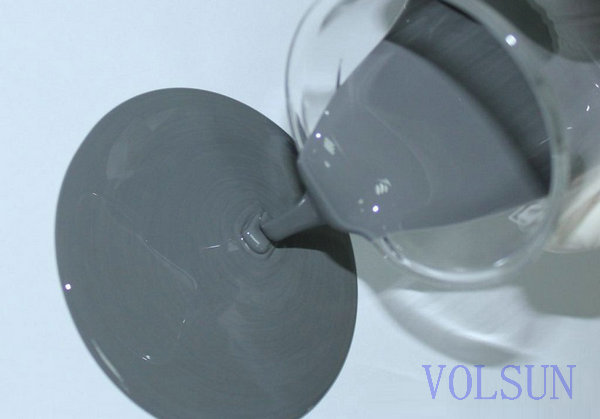

- Low viscosity, self-leveling, excellent seam drilling ability

- Low modulus, low stress, good adhesion to metals and plastics

And you can check the below technical performance data to know more details:

| Item | Typical value | Test method |

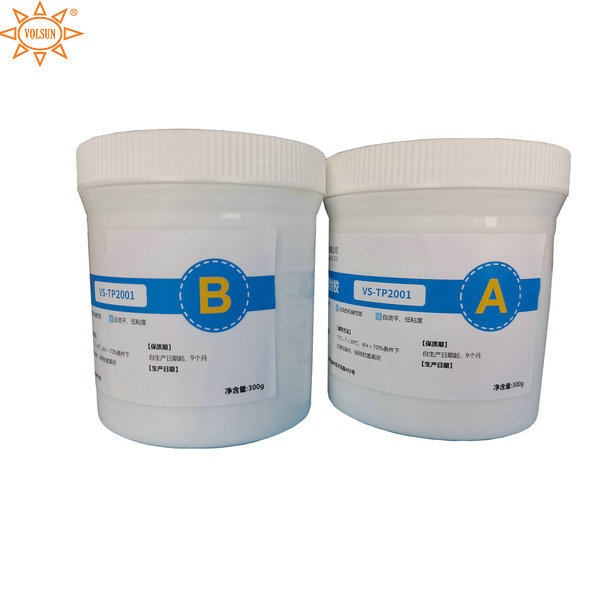

| Mixing ratio | 1:1 | / |

| Color(After mixing) | Grey | Visual inspection |

| Viscosity(Component A) @25℃ | 2500±500cps | ASTM D2196 |

| Viscosity(Component B) @25℃ | 2500±500cps | ASTM D2196 |

| Viscosity(After mixing) @25℃ | 2500±500cps | ASTM D2196 |

| Opening hours@25℃ | ≥60min | / |

| Curing condition | 30min/50℃;20min/100℃ | / |

| Thermal conductivity | 1.0±0.2 W/m·k | ASTM D5470 |

| Thermal resistance | 0.000815m2·k/W | ASTM D5470 |

| hardness | 65±5 Shore A | GB/T 531.1-2008 |

| density | 2.0±0.2 g/cm3 | GB/T 1033.1-2008 |

| Tensile strength | >0.5 MPa | GB/T 528-2009 |

| Elongation at break | >10% | GB/T 528-2009 |

| Flame retardant rating | V-0 | UL94 |

| Breakdown strength | ≥15 kV/mm | GB/T 1695-2005 |

| Volume resistivity | ≥ 1.0×1014 Ω·cm | GB/T 1692-2008 |

| Dielectric constant (1000Hz) | 3.9~4.6 | GB/T 1693-2007 |

| Type | Packing |

| VS-TP1001(1kg) | Component A 0.5kg; Component B 0.5kg |

| VS-TP1001(20kg) | Component A 10kg; Component B 10kg |

| VS-TP1001(40kg) | Component A 20kg; Component B 20kg |

| VS-TP1001(80kg) | Component A 40kg; Component B 40kg |

| VS-TP1001(100kg) | Component A 50kg; Component B 50kg |

Instructions

- Stirring A and B components separately

- Mixing the well-stirred components A and B at the ratio of 1:1 (either volume ratio/weight ratio can be used)

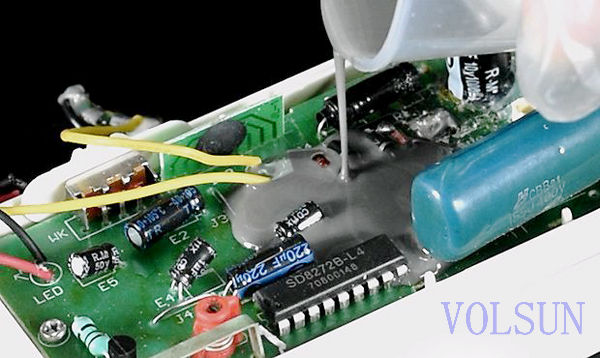

- The mixed compound is poured into the device to be filled and cured (room temperature or heating can be cured).

- In order to ensure the uniform distribution of fillers, component A and component B must be separately stirred before mixing, so that each compound is evenly mixed

- A and B agents will react and cure each other after mixing, so they need to be used after mixing, and can not be used twice after mixing and curing

- When pouring into the protective part, there should be no large debris or other pollutants in the protective part to avoid affecting the adhesion of materials and objects

- Before the material is fully cured, keep other objects away from the material, which may affect the appearance and protective performance of the material

- Keep this product away from the mouth and eyes. If it enters the mouth and eyes accidentally, rinse it with clean water or go to the hospital

- For high thermal conductivity, vacuum defoaming is required prior to perfusion

- In low temperature environment, the curing time will be extended correspondingly

- Products should be stored in the original packaging, keep the lid closed, avoid contamination (temperature: 15℃ < T < 30℃; Relative humidity: RH < 70%)

- The shelf life is 9months from the production date

Welcome to contact us at any time if any questions or needs.

- CONTACT TEL: +86-512-66386808

- SALES CONTACT: volsun2006@szvolsun.com